Good 480 V 3 Phase Motor Readings

Motor windings are conductive wires wrapped around a magnetic core; they provide a path for current to flow to create then magnetic field to spin the rotor. Similar any other part of the motor, the winding can fail. When motor windings neglect it's very seldom that the bodily conductors neglect, rather it is the polymer coating (insulation) surrounding the conductors that fail. The polymer material is organic in its chemical composition and is field of study to change due to aging, carbonization, heat, or other adverse conditions that cause a chemical limerick of polymer material to change. These changes cannot exist detected visually, or even with traditional electrical testing instruments like ohmmeters or megohmmeters.

The sudden failure of any part of the motor will cause loss of production, increased maintenance expense, loss, or damage to majuscule and perchance personal injury. Since nigh insulation failure occurs over fourth dimension, MCA engineering provides the measurements required to place these modest changes that make up one's mind the condition of the winding insulation system. Knowing how to cheque your windings volition allow your team to exist proactive and take the appropriate action to foreclose unwanted motor failure.

How to Test Groundwall Insulation

A footing error or a short to footing occurs when the resistance value of the basis wall insulation decreases and allows the current to flow to footing or an exposed part of the machine. This creates a prophylactic result since it provides a path for the supply voltage from the winding to extend to the frame or other exposed parts of the machine. To exam the condition of the ground wall insulation measurements are made from the winding leads T1, T2, T3 to ground.

Best practices test the winding path to ground. This test provides a DC voltage to the motor winding and measures how much current flows through the insulation to footing:

ane) Examination the motor de-energized past using a properly working voltmeter.

two) Place both instrument exam leads to ground and verify a solid connectedness to ground of the musical instrument lead. Measure the insulation resistance to footing (IRG). This value should exist 0 MΩ. If any value other than 0 displays, reconnect the examination leads to ground and retest until a 0 reading is obtained.

3) Remove one of the test leads from basis and connect to each of the motor leads. And so measure the insulation resistance value of each atomic number 82 to ground and verify the value exceeds the recommended minimum value for the motors supply voltage.

NEMA, IEC, IEEE, NFPA provide diverse tables and guidelines for the recommended test voltage and minimum insulation to ground values dependent on the motors supply voltage. This test identifies any weaknesses in the groundwall insulation system. The dissipation gene and capacitance to ground test provide boosted indication of the overall condition of the insulation. The testing procedure for these tests are the aforementioned, just instead of applying a DC voltage, an Air conditioning signal is applied to provide better indication of the overall condition of the groundwall insulation.

How to Test Your Windings for Connection Bug, Open or Shorts

Connection issues: Connection problems create electric current unbalances between the phases in a 3-phase motor, which causes excess heating and premature insulation failure.

Opens: Opens occur when a conductor or conductors break or separate. This may preclude the motor from starting or cause information technology to run in a "unmarried-phase" condition, which draws excess current, overheating of the motor and premature failure.

Shorts: Shorts occur when the insulation surrounding the winding conductors breaks down between conductors. This allows the current to flow between conductors (short) instead of through the conductors. This creates heating at the fault leading to further degradation of the insulation between conductors and ultimately leads to failure.

Testing for winding faults requires performing a serial of Air-conditioning & DC measurements made between the motor leads and the measured values are compared, if the measurements are balanced winding are OK if they are unbalanced faults are indicated.

The recommended measurements are:

i) Resistance

two) Inductance

iii) Impedance

4) Stage Angle

5) Current Frequency Response

Test your winding status by testing these connections:

- T1 to T3

- T2 to T3

- T1 to T2

The reading should be betwixt 0.3 to 2 ohms. If it is 0, there is a short. If information technology is over 2 ohms or infinite, there is an open up. You tin can also dry the connector and retest to possibly get more accurate results. Check the inserts for burn marks and cables for vesture.

Resistance unbalance indicates connection issues, if these values are out of balance by more than than 5% from boilerplate, this indicates loose, high resistance connectedness, corrosion or other build upwards on the motor terminals. Make clean the motor leads and retest.

Opens are indicated past space resistance or impedance reading.

If the stage angle or current frequency responses are out of balance by more 2 units from average, this may indicate winding shorts. These values could exist affected past the position of the squirrel muzzle rotor during testing. If the impedance and inductance are out of residual by more than than 3% from boilerplate, information technology is recommended to rotate the shaft approximately xxx degrees and retest. If the unbalance follows the rotor position, the unbalance could be the result of the rotor position. If the unbalance remains the same a stator fault is indicated.

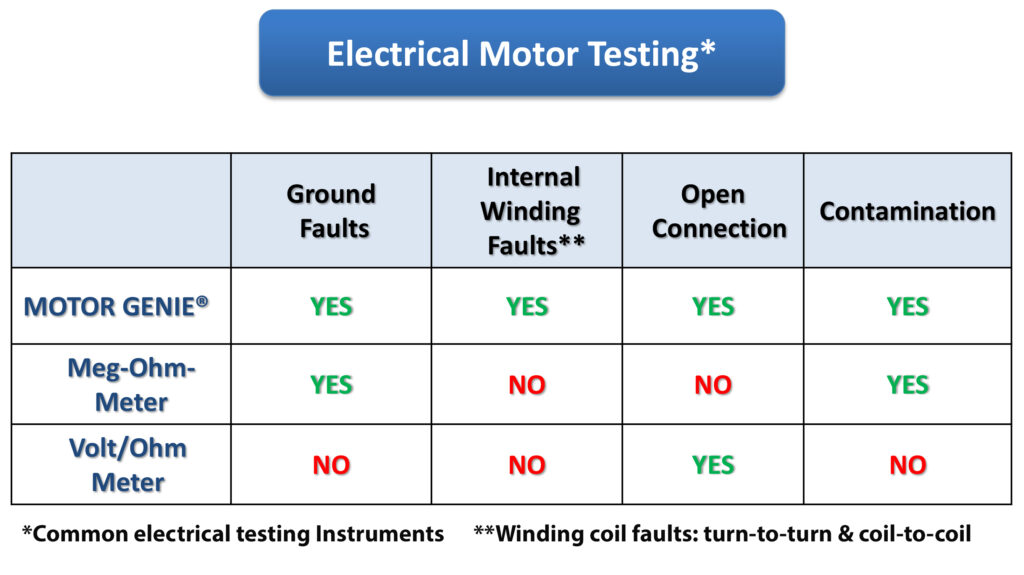

Traditional Motor Testing Instruments Are Not Able to Test or Check Motor Windings Finer

The traditional instruments used for testing motors take been the megohmmeter, the ohm meter, or sometimes a multimeter. This is because of the availability of these instruments in most plants. The megohmmeter is used for rubber testing of electrical equipment or systems and the multi-meter is used to perform most other electrical measurements. Yet, neither of these instruments past themselves or combined provides the information necessary to properly evaluate the condition of a motor'south insulation system. The megohmmeter can identify weaknesses in the motor's groundwall insulation but does non provide the overall condition of the insulation organisation. It as well does not provide information virtually the condition of the winding insulation organization. The multi-meter will identify connection issues and opens in the motor windings but provides no information about the insulation betwixt the windings.

Test Windings With Motor Circuit Assay Testing (MCA™)

Motor circuit analysis testing (MCA™) is a deenergized method that will thoroughly assess your motor health by checking windings and other parts. Information technology is piece of cake to apply and apace delivers accurate results. The ALL-TEST PRO 7™, ALL-TEST PRO 34™ and other MCA™ products can be used on any motor to place potential issues and avert costly repairs. MCA fully exercises the motors winding insulation system and identifies early deposition of the winding insulation system, besides as faults within the motor that lead to failure. MCA also diagnoses loose and faulty connections when the tests are performed from the motor controller.

Request a Quote for Motor Testing Equipment Today

Motor testing is necessary because motors fail, and testing can place problems that will prevent failure. At ALL-Examination Pro, nosotros have a broad selection of motor testing products suitable for many industries. Nosotros take worked with technicians from food processing, small motor shops, electrical repair and more than. Compared to the competition, our machines are the fastest and lightest while providing valuable results without the need for additional data interpretation.

Request a quote on our website today to get pricing information for our motor testing products. For more information about how to check your windings, contact our team online.

sinclairnosem1957.blogspot.com

Source: https://alltestpro.com/blog-how-to-check-your-windings/

0 Response to "Good 480 V 3 Phase Motor Readings"

Post a Comment